- This topic is empty.

-

AuthorPosts

-

20/11/2025 at 15:31 #4277

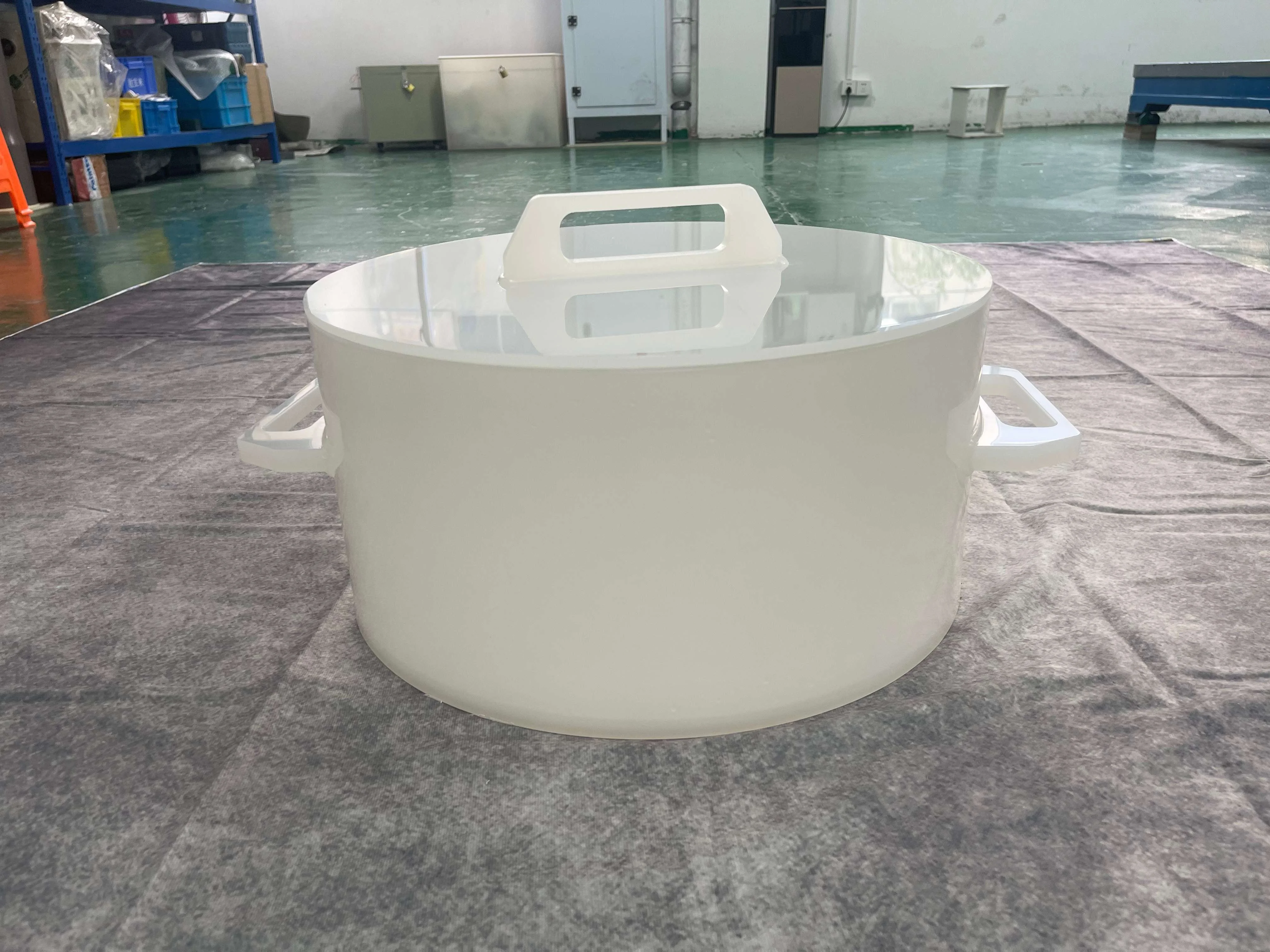

In laboratory and industrial environments, handling liquids safely, efficiently, and accurately is essential. The right NPP liquid bucket can significantly improve workflow, reduce contamination risk, and enhance overall productivity. Whether you’re working in semiconductor fabrication, chemical laboratories, or other high-precision industries, selecting the correct liquid bucket is critical to maintaining quality, safety, and operational efficiency.

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. is a leading developer and manufacturer of plastic equipment for laboratories and the semiconductor industry. From prototype development to mass production, Xinruiwei provides customized solutions built with European components in China, ensuring top-quality products with reliable delivery. Their expertise in plastic equipment makes them a trusted partner for NPP liquid bucket solutions tailored to your application needs.

1. Understand Your Application Requirements

The first step in choosing the right NPP liquid bucket is to analyze your specific application. Consider factors such as:

-

Type of liquids (acids, bases, solvents, or water-based solutions)

-

Temperature range and chemical compatibility

-

Required volume capacity

-

Frequency of use

Selecting a bucket that matches these criteria ensures chemical resistance, durability, and accurate handling, reducing risks of spills, leaks, or equipment damage.

2. Material and Chemical Resistance

NPP liquid buckets are typically made from high-quality plastics designed to resist corrosion, chemical attack, and UV degradation. Materials like PP (polypropylene) or HDPE (high-density polyethylene) are commonly used for their excellent chemical resistance and mechanical strength.

Xinruiwei Semiconductor Technology uses premium European components and high-quality plastics to manufacture their liquid buckets. This ensures that the buckets maintain structural integrity and chemical resistance even under demanding laboratory or industrial conditions.

3. Capacity and Design Considerations

Selecting the correct volume capacity is crucial for operational efficiency. NPP liquid buckets come in various sizes to accommodate small-scale experiments or large industrial processes. Key design factors include:

-

Stackability for easy storage

-

Spill-proof lids or pouring spouts

-

Graduated markings for accurate measurement

Xinruiwei’s liquid buckets are designed with practical features that enhance ease of handling and workflow efficiency, making them suitable for both lab-scale and industrial-scale operations.

4. Ease of Cleaning and Maintenance

A critical factor in laboratory and industrial environments is cleanliness. NPP liquid buckets should be easy to clean and sterilize to prevent cross-contamination between batches or processes.

-

Smooth interior surfaces minimize residue buildup

-

Autoclavable or chemical-resistant designs extend usability

-

Detachable components simplify thorough cleaning

Xinruiwei’s designs prioritize hygiene and low-maintenance operation, ensuring that buckets remain safe and reliable over repeated use.

5. Customization and Compliance

Different applications may require customized features, such as specialized handles, lids, or integrated filtration systems. Xinruiwei offers tailored NPP liquid bucket solutions, allowing clients to adapt buckets to their specific workflows.

Additionally, compliance with industry standards ensures that buckets are safe for laboratory and industrial use, meeting both national and international regulations for material safety and performance.

Conclusion

Choosing the right NPP liquid bucket requires careful consideration of application requirements, material compatibility, design features, and maintenance needs. Selecting an unsuitable bucket can lead to contamination, spills, and inefficiency, while the right choice enhances safety, workflow, and overall productivity.

With Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd., clients benefit from high-quality, customizable plastic equipment manufactured with European components and Chinese precision. Their liquid buckets are ideal for laboratories and semiconductor applications, providing reliable, durable, and efficient solutions for handling a wide range of liquids.

For anyone looking to optimize liquid handling in laboratory or industrial settings, investing in a carefully selected NPP liquid bucket from Xinruiwei is a smart step toward safer and more productive operations.

http://www.wafera.com

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.