- This topic is empty.

-

AuthorPosts

-

16/06/2025 at 16:49 #3277

In today’s rapidly evolving industrial landscape, flexibility, scalability, and efficiency are more than just buzzwords—they're essential elements for modern process development and production. Whether in chemical engineering, pharmaceuticals, petrochemicals, or advanced materials, manufacturers are seeking smarter ways to deploy and manage process equipment.

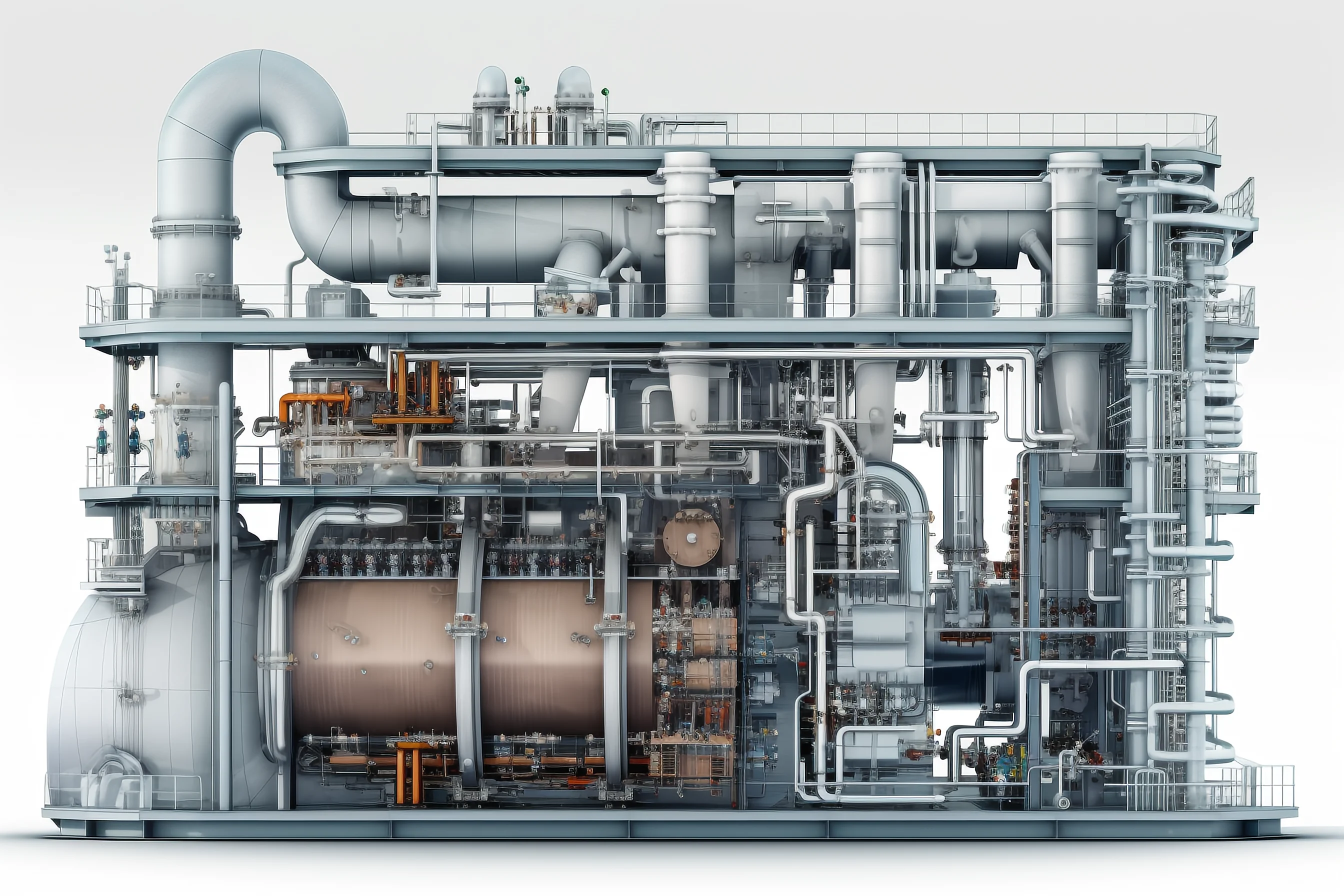

That’s where skid-mounted unit systems come into play. As modular, self-contained systems designed for plug-and-play installation, skid-mounted solutions are transforming the way businesses approach pilot testing, scale-up, and production.

In this blog post, we’ll explore the key advantages of skid-mounted unit series and highlight why Chem-Unit, a leader in the design, development, manufacturing, and technical service of modular equipment, is a top choice for advanced modular solutions.

What Is a Skid-Mounted Unit?

A skid-mounted unit is a compact and fully integrated equipment system built on a steel skid or base frame. These units are pre-assembled, pre-wired, and pre-tested at the manufacturing facility, making them ready for rapid on-site installation with minimal additional work.

Skid-mounted solutions typically include:

Process vessels

Pumps and compressors

Instrumentation and control panels

Piping, valves, and fittings

Electrical and automation systems

Because they are modular, multiple skids can be connected or expanded according to project needs—offering unparalleled flexibility in R&D, pilot testing, and industrial-scale operations.

Top Advantages of Skid-Mounted Unit Series

1. Plug-and-Play Installation

Skid-mounted units are fully assembled and tested off-site, enabling fast deployment upon arrival. This reduces site construction time, minimizes downtime, and accelerates project commissioning.

2. Mobility and Portability

Since skid-mounted systems are self-contained and compact, they can be easily relocated or reconfigured for different testing or production environments. This is ideal for multi-site operations or pilot plants.

3. Reduced Construction and Engineering Costs

The pre-fabricated nature of skid systems eliminates the need for extensive on-site engineering, welding, or installation. Labor and infrastructure costs are significantly lowered compared to traditional fixed systems.

4. Improved Safety and Quality Control

Skid-mounted units are fabricated under controlled factory conditions, which means higher quality assurance and better safety compliance. Testing is performed before delivery, reducing commissioning risk on-site.

5. Modularity and Scalability

Modular skid units can be added, upgraded, or integrated into existing systems as production needs evolve. This makes them ideal for pilot-scale trials, scale-up processes, and phased industrial expansion.

6. Compact Footprint

Skid systems are designed to optimize space without sacrificing performance. For facilities with limited floor area or cleanroom requirements, skid-mounted equipment provides high functionality in a small package.

7. Versatility Across Applications

From chemical reaction testing and process simulation to batch and continuous production lines, skid-mounted units can be customized for a wide range of industries, including fine chemicals, biopharma, energy, and materials engineering.

Why Chem-Unit Leads in Skid-Mounted Solutions

Chem-Unit is at the forefront of modular equipment innovation. With a specialized focus on skid-mounted pilot systems, intermediate (mid-scale) plants, production units, and custom-built robotic lab equipment, the company provides turnkey solutions for complex process challenges.

Chem-Unit’s Competitive Strengths:

R&D Excellence: Chem-Unit’s engineering team offers cutting-edge design tailored to client-specific needs—from early-stage experimental systems to commercial production platforms.

Full Lifecycle Support: Services include not only design and manufacturing, but also installation, commissioning, training, and ongoing technical support.

Automation & Intelligence: Many units integrate smart controls, data acquisition, and remote monitoring—essential features for modern, data-driven process environments.

Custom Modularization: Chem-Unit delivers both standardized units and highly customized skids, suitable for chemical synthesis, catalysis studies, thermal processes, and more.

Collaborative Innovation: The company works closely with research institutions, industrial partners, and tech developers to ensure systems are future-ready.

Whether you need a single-process skid or a complete modular pilot plant, Chem-Unit delivers high-performance equipment that bridges R&D and scalable production with unmatched precision.

Final Thoughts

In an era where speed, adaptability, and cost-efficiency are critical, skid-mounted unit series provide a powerful solution for both experimental and production-scale operations. Their compact, flexible, and high-performance nature makes them indispensable in sectors ranging from chemical engineering to high-end manufacturing.

With Chem-Unit’s expertise in modular design, intelligent control, and technical integration, businesses gain more than just equipment—they gain a partner in innovation.

If you're looking to simplify complexity and scale smartly, skid-mounted modular systems by Chem-Unit are your ideal solution.

5 Common Problems Solved by Skid-Mounted Units

en.chem-unit.com

Key Features of Skid-Mounted Units for Efficient Chemical Processing -

AuthorPosts

- You must be logged in to reply to this topic.